by Patrick Skahill

(c) Connecticut Explored Inc. WINTER 2010/11

Subscribe/Buy the Issue!

Front window of Smith-Worthington’s

New York City showroom, early 20th century.Smith-Worthington Saddlery Co

In 1958, a soft-spoken Muslim man, followed by a retinue of 10 people, walked into Hartford’s Smith-Worthington Saddlery Co. on Sigourney Street in Hartford. The man was dignified, projecting a charismatic air of authority that was underscored by his obvious wealth. As he spoke with saddle makers in the shop, the mysterious visitor complimented their work, calling it some of the most detailed he had ever seen. The man quietly met with the owner, Clinton Hanks, and placed an order for 12 custom-made saddles. And then—just as quickly as he appeared— the stranger and his retinue disappeared. Workers in the shop were perplexed but quickly started on the lucrative contract.

A few weeks later, an official-looking letter arrived at the factory. Surprised, Hanks broke the letter’s seal, pulled out its contents, and took a moment to catch his breath. The visitor, this letter revealed, had been Mohammad Reza Pahlavi, the shah of Iran. He wrote that he’d heard about Smith-Worthington’s reputation for quality design and handmade craftsmanship and couldn’t think of any other saddle he would rather have on the horses of his court. Members of the American embassy urged Hanks to expedite the order.

Founded in Hartford in 1794 by Normand Smith, Smith-Worthington Saddlery, makers of saddles and a wide range of related equipment (tack) for horseback riders, began as a modest operation but caught on quickly, in large part because Smith marketed many of his products to women—a segment of the riding population sorely underserved at the time. In the 1830s, Smith opened a shop in New Orleans, and by 1842 the company opened a satellite facility in New York City. The company changed partners and names many times and finally became Smith-Worthington when the Hartford and New York concerns merged in 1905.

Business continued to expand and adapt in wartime. The company made saddles for both the Union and Confederate armies during the American Civil War and secretly outfitted Cuban revolutionaries during an insurrection against Spain in 1895.

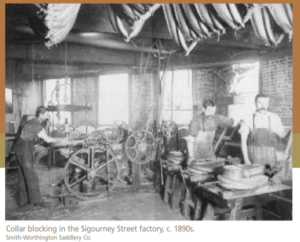

But it was World War I that skyrocketed the company to the height of its production. Smith-Worthington branched out into all aspects of the leather market, employing more than 1,000 workers around the clock. The factory made thousands of machine-gun harnesses, ammunition belts, saddles, and horse bridles. Production was so heavy that the company—fearful of infiltration by German spies—contracted Hartford Police officers for late-night guard duty.

When the World War I ended, however, production sharply dropped. Smith-Worthington retooled, scaled back production, and refocused its energy on making saddles—catering to recreational horse riders—while gingerly branching out into the automobile accessories industry. Smith-Worthington also never ignored a custom-designed order, no matter how “crazy.” Company workers drew up plans for several oddball saddle prototypes, including a camel saddle and one for an elephant, along with harnesses for ostriches and seals.

Compared to World War I’s around-the-clock shifts, manufacturing was relatively quiet during the Depression. During World War II and the German Blitz, when the bobbies of England—who traditionally didn’t carry guns—were issued firearms, Smith-Worthington made the holsters. But the need for saddles in wartime was disappearing.

Throughout the 20th century Smith-Worthington’s designers have been forced to innovate, adapt, and respond to unorthodox consumer requests. This versatility caught the attention of many new customers asking for new products. Antarctic explorer Richard E. Byrd used Smith-Worthington equipment to outfit his dogs during his expedition of 1928. NASA—through Connecticut-based Hamilton Standard—employed Smith-Worthington experts as leather-sewers on prototype space suits in the 1960s. The company’s master saddler and saddle foreman Nicholas Mitesser, who designed Shah Pahlavi’s saddles, also made saddles for entertainment icon Arthur Godfrey and President Theodore Roosevelt’s grandson, John Roosevelt. Yale University asked the company to produce a custom leather harness to hold an experimental pacemaker in place on a pig. Perhaps the strangest request came in 1991, when the American embassy in Abu Dhabi forwarded a request for camel shoes to be used in training events for the country’s multi-million-dollar camel races.

Today, Smith-Worthington is owned by Curtis Hanks, son of Clinton. The Hankses are only the third family to have owned the company. They purchased it some time after World War II from John Alan Roberts, who had owned it since 1928. In June 1961, the five-story plant on Sigourney Street was razed to make way for a portion of Interstate 84 and the company moved to 287 Homestead Avenue in Hartford, where operations continue today.

Making saddles is time-consuming work, and Curtis Hanks describes the craft as taking a lifetime to master—and even then, he said, there’s still so much more to learn. “You have to have a real passion for making saddles,” he says. “It’s a niche industry in a niche market.”

Making saddles is time-consuming work, and Curtis Hanks describes the craft as taking a lifetime to master—and even then, he said, there’s still so much more to learn. “You have to have a real passion for making saddles,” he says. “It’s a niche industry in a niche market.”

Smith-Worthington faces an uncertain future as the rising cost of owning and maintaining a horse constrains the market. After more than 200 years of saddle-making in Hartford, however, company executives temper that fear with faith that their commitment to quality, handmade production will continue to attract clients. From heads of government to a young girl just learning how to ride, Smith-Worthington hopes to continue making saddles for riders of all kinds for years to come. After all, they have been, as their tag line says, “crafting fine English saddlery and tack since George Washington was President.”

Patrick Skahill is a radio producer, freelance writer, and reporter in Collar blocking in Connecticut

Explore!

Read more stories about products made and invented in Connecticut on our TOPICS page.