(c) Connecticut Explored Inc. SPRING 2005

Subscribe/Buy the Issue!

The imposing statue of The Genius of Connecticut in the north lobby of the State Capitol is captivating. It is an impressive reminder of brilliant innovation, entrepreneurial skill, and the stomach for risk-taking that has been the trademark of Connecticut. L. Sprague De Camp expressed it well in The Ancient Engineers: “Civilization, as we know it today, owes its existence to the engineers. These are the men who, down the long centuries, have learned to exploit the properties of matter and the sources of power for the benefit of mankind.”

One such innovator was Frederick Brant Rentschler (1887 – 1956), the son of a German  immigrant. When the United States entered WWI, the Princeton-educated Rentschler joined the Army Air Service, the precursor to the U.S. Air Force, and was quickly assigned to represent the government overseeing the production of the Hispano-Suiza engine at the Wright-Martin Company in New Brunswick, New Jersey. One of the best aircraft in WWI, the very successful SPAD, used this engine. Eddie Rickenbacker, in the Lafayette Escadrille (the Flying Circus) and other top aviators in France flew the SPAD.

immigrant. When the United States entered WWI, the Princeton-educated Rentschler joined the Army Air Service, the precursor to the U.S. Air Force, and was quickly assigned to represent the government overseeing the production of the Hispano-Suiza engine at the Wright-Martin Company in New Brunswick, New Jersey. One of the best aircraft in WWI, the very successful SPAD, used this engine. Eddie Rickenbacker, in the Lafayette Escadrille (the Flying Circus) and other top aviators in France flew the SPAD.

At the end of the war, in 1918, most of Wright-Martin, which had been set up to manufacture Hispano-Suiza engines for the war effort, planned to close and its assets were sold. However, about $3 million was put aside for the founding of Wright Aeronautical Corporation. Prior to his military assignment in WWI, Rentschler had accumulated eight years of business experience in his family’s enterprises: Republic Motor Car, Hooven-Owens-Rentschler Company, and the Hamilton Foundry and Machine Company. With his business background and knowledge of engines, not to mention his wartime contacts, Rentschler was offered the position of vice-president and general manager and was promised the position of president within a year. Rentschler served out his time in the military and in 1919 joined Wright Aeronautical.

Rentschler offered jobs in the new company to George J. Mead as engineering vice president, Andrew Willgoos as chief engineer, Charles Marks to head up production engineering, John Borrup for shop supervision and Don Brown for overall factory management. Not all of them came directly to the fledgling company. Mead preferred to gain more aircraft engine experience by working at the Air Corps Powerplant Laboratory at McCook Field for about a year. Henry Crane, chief engineer at Wright-Martin, agreed to fill in until Mead joined Wright Aeronautical. Don Brown took a position with an automobile company before going to work at Wright Aeronautical. This was the formation of a winning team that would later make major innovations in aircraft engines in Hartford, Connecticut .

The Air-Cooled Engine

Over the next five years Wright Aeronautical produced excellent liquid-cooled engines of its own design while also making improvements in the Hispano engines, the company’s first product. In the meantime Rentschler began making good contacts in the Navy and Army aviation departments.

top: the c. 1926 Pratt & Whitney Wasp engine as illustrated in a mid-1950s advertisement for the United Aircraft Corporation’s fight development program. Colliers Magazine, February 1954. Museum of Connecticut History. Below: Frederick Rentschler in front of Pratt & Whitney Aircraft office. Courtesy of Pratt & Whitney

At that time aircraft engines were of two general types-liquid-cooled and air-cooled-though in the early 1920s air-cooled engines were still unreliable. During a visit to France just before WWI American Charles Lawrance, originally a designer of engines for racing cars, was impressed with the French air-cooled engine technology. He immediately saw the potential for aircraft carrier operation because of the air-cooled engine’s potential for lighter weight per horsepower and set about getting the U.S. Navy’s attention. His efforts paid off. The Navy was interested in ordering a significant number of Lawrance’s engines for evaluation. However, Lawrance’s small engineering staff and the limited manufacturing facilities of the Lawrance Aero-Engine Corporation lacked the capability for large-scale production as well as the test facilities to develop a reliable engine. The Navy’s bureau of aeronautics wanted the Lawrance J-1 engine but the only way it could be developed would be if Wright Aeronautical could bring it through the development process. In the early 1920s Wright Aeronautical bought the Lawrance Aero-Engine Corporation and Lawrance became a vice president. Wright Aeronautical’s engineering staff improved the Lawrance J-1 engine and launched the subsequent chain of successful Wright Whirlwind engine models-all, as the name implies, air-cooled. A later model, the J-5, was used in Lindbergh’s “Spirit of St. Louis” when he flew nonstop to France in 1927.

The Visionary Rentschler Comes to Hartford

In 1925 Rentschler came to Hartford to discuss a new aircraft engine venture with the Pratt & Whitney Company. Commercial aviation, in the modern sense where one could fly from New York to Los Angeles on one airline, did not exist yet. Aviation was still in its adventure phase and the general public rightly perceived it as dangerous. Rentschler had a vision for viable commercial aviation and an expansion of military aviation by the use of dependable air-cooled engines. Rentschler had resigned as president of Wright Aeronautical because his board of directors was hesitant to invest for the long haul. They, as bankers, preferred to see a quicker return on their assets rather than investing in research and development, whose results in terms of timing and profitability were uncertain.

Rentschler and Pratt & Whitney complemented each other perfectly. Rentschler brought his vision and the small group of highly competent men he’d assembled at Wright Aeronautical to realize that vision. For its part, the Pratt & Whitney Company had surplus cash to invest and idle factory space. Rentschler, now in competition with Wright Aeronautical, also had a plan to demonstrate to the U.S. Navy that air-cooled engines were lighter and more suitable for shipboard use than the liquid-cooled engines. After he had convinced the navy’s experts he planned to approach the Army Air Corps, the name by which the Army Air Service was then known. At this point in time the Army Air Corps was committed to liquid-cooled engines because of the belief that these engines would have lower installed drag due to their smaller frontal area compared to radial air-cooled engines of the same horsepower. Though theoretically the lower drag would make the plane go faster, the lighter weight of the air-cooled engines more than offset their higher drag. The commitment to liquid-cooled engines was eventually abandoned; in WWII air-cooled engines provided 85 percent of the aircraft engine horsepower.

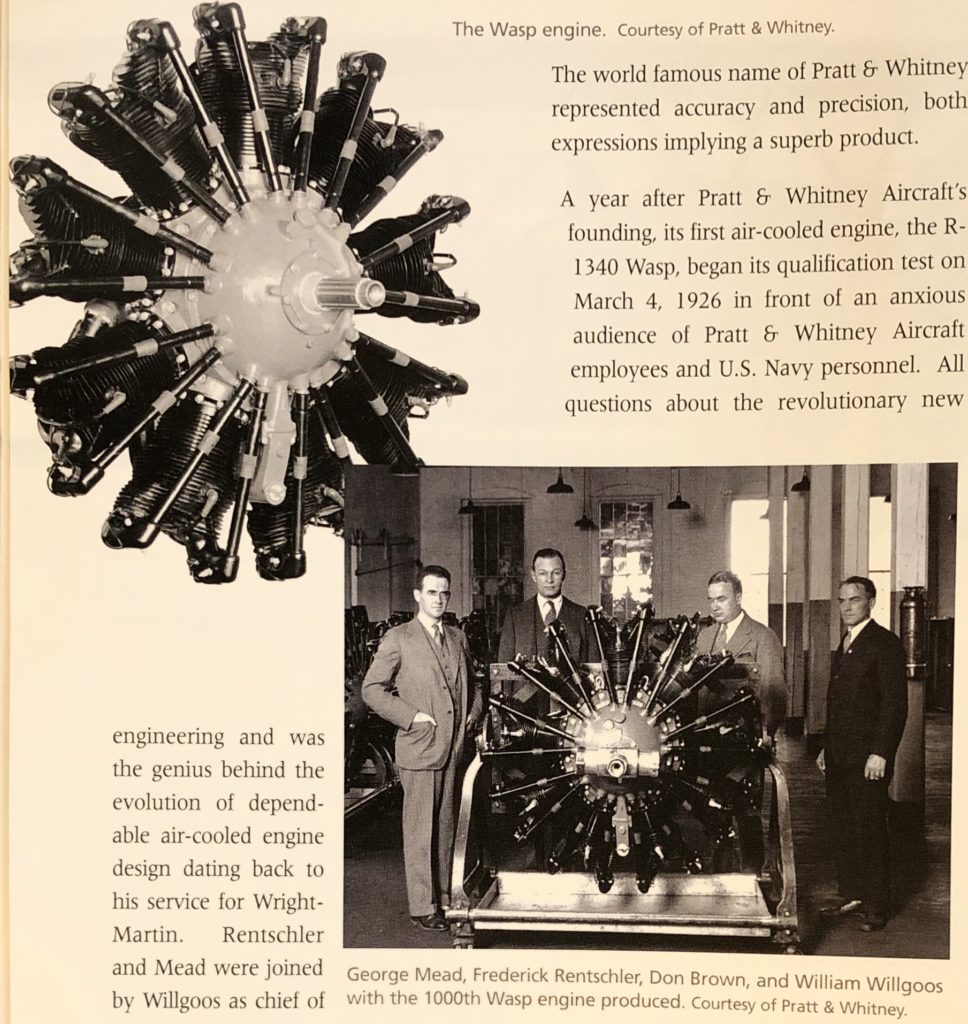

The outcome was the formation of The Pratt & Whitney Aircraft Company on July 14, 1925. The new company’s cofounder was George Mead, who became vice president of engineering and was the genius behind the evolution of dependable air-cooled engine design dating back to his service for Wright-Martin. Rentschler and Mead were joined by Willgoos as chief of design, Brown as factory manager, Borrup as superintendent, and Marks as production engineer. The new company was a partnership with a nominal amount of common shares: 50 percent were owned by the Pratt & Whitney Company and 50 percent were owned by Rentschler and Mead. Rentschler estimated capital requirements to bring the first air-cooled engine to success and preferred stock was issued to Niles-Bement-Pond (the parent of the Pratt & Whitney Company) to finance the new engine’s development.

The new company adopted a logo that consisted of an eagle in flight enclosed in a circular ring of letters spelling out Pratt & Whitney U.S.A and Dependable Engines. The world famous name of Pratt & Whitney represented accuracy and precision, both expressions implying a superb product.

A year after Pratt & Whitney Aircraft’s founding, its first air-cooled engine, the R-1340 Wasp, began its qualification test on March 4, 1926 in front of an anxious audience of Pratt & Whitney Aircraft employees and U.S. Navy personnel. All questions about the revolutionary new engine were laid to rest when it topped out at full throttle at 420 horsepower. The U.S. Navy purchased the engine for its shipboard fighter aircraft in late 1926. The next engine in 1927 was called the Hornet R-1690 at 525 horsepower, which distinguished itself later in Sikorsky flying boats that mapped out the air routes across the Atlantic and Pacific oceans, over the Caribbean Sea and throughout South America . In the late 1930s the Wasp provided 600 horsepower and the Hornet 875 horsepower.

Rentschler & Boeing Create Commercial Aviation

William Boeing had been in the airplane manufacturing business in Seattle since 1916 as well as flying the airmail since the late 1920s. When he switched from liquid-cooled engines to Pratt & Whitney’s Wasp engine, he discovered that he could carry more mail because of the lighter engine. After only two years flying with Wasps, Boeing Air Transport planes had flown 5,500,000 miles, delivered 1,300 tons of mail and-beginning to realize Rentschler’s vision of commercial aviation–carried 6,000 passengers. Boeing Air Transport was able to provide mail service at about a third of the cost of aircraft powered by liquid-cooled Liberty engines. He was so impressed with the Wasp that he approached Rentschler and suggested they team up. Their new company became The United Aircraft & Transport Corporation (UA&TC); Rentschler became the president of UA&TC and Boeing the chairman. The new company’s activities included engine and aircraft manufacturing, airport services and airlines. It made transcontinental air travel possible through the use of comfortable aircraft, extensive airline routes for that time period and, of course, dependable engines.

top: the Wasp engine. below: George Mead, Frederick Rentschler, Don Brown, and William Willgoos with the 1000th Wasp engine produced. Courtesy of Pratt & Whitney

But all was not smooth flying. In the early 1930s, right after President Franklin Roosevelt’s inauguration, Senator Hugo Black of Alabama chaired the Special Committee to Investigate Air Mail and Ocean Mail Contracts. There were allegations that air mail contracts under Postmaster General Walter Folger Brown were awarded in accordance with “a spoils system.” These allegations ultimately proved to be false. But according to Rentschler, the committee seemed to also focus on the success of United Aircraft & Transport Corporation. Though Rentschler argued that United Aircraft & Transport Corporation was being unfairly scrutinized and had not done anything any other company with a taste for a high-risk business venture could have done, the Black-McKeller Act, known as the Air Mail Act of 1934, forced the break up United Aircraft & Transport Corporation. William Boeing was so disgusted he quit aviation. Rentschler, in An Account of Pratt & Whitney Aircraft Company, 1925-1950 , wrote, “It was of no interest to the investigators the contribution which United, its subsidiaries, and its personnel as a whole, had made to both military and transport aviation.” Subsequently in 1934, Rentschler put together United Aircraft Corporation, which comprised Pratt & Whitney Aircraft, Hamilton Standard Propellers, Chance Vought Aircraft, and Sikorsky Aircraft. William Boeing’s collection of airlines merged into United Air Lines.

P&W Aircraft’s Contribution to WWII Victory

As World War II approached President Roosevelt appointed William Knudsen of General Motors to head up the Office of War Production. George Mead, who had resigned from P&W in 1939, became one of Knudsen’s first executives for aviation. Mead proceeded to do a masterful job in getting the automotive companies into the production of aircraft engines.

P&W Aircraft’s magnificent combination of accuracy and dependability became evident during WWII in the more than 360,000 Pratt & Whitney piston engines produced by Ford, Buick, Chevrolet, Nash-Kelvinator, Continental, Jacobs, Commonwealth Aircraft (Australia), Canadian Pratt & Whitney, P&W East Hartford and P&W Kansas City-a significant contribution to establishing air superiority in WWII. These Pratt & Whitney engines provided about half the total aircraft engine horsepower in WWII. Furthermore, Rentschler did something totally unheard of when doing business with the government. He gave back money as he found his costs were less than he estimated in the contract. Secretary of the Navy James Forrestal personally thanked Rentschler (in a letter dated March 30, 1946) for furnishing the impetus for the Renegotiation Act.

P&W Aircraft over the Past 50 Years

In 1958 P&W Aircraft with The Boeing Company and Douglas Aircraft Company (founded in 1921) launched luxury jet travel with the B-707; they followed this up in 1959 with the DC-8. In the mid-1960s P&W’s JT8D engine ushered in a new era in commercial air transportation in the Boeing B-727 and B-737 along with the Douglas DC-9. In January 1970 Boeing with its B-747 and P&W’s JT9D launched wide-body luxury air travel.

Before WWII, Pratt &Whitney granted manufacturing licenses to BMW in Germany and Mitsubishi in Japan for the Hornet piston engine. By the 1970s there was full collaborative partnership in new engines, starting with the design and all the way through development, production, sales and product support. In response to the global business realities Pratt & Whitney joined with Rolls-Royce, Japanese Aero Engines Corporation, MTU and FIAT to form International Aero Engines (IAE) in 1983. Their V2500 engine has been a great success and has demonstrated that it’s possible to operate effectively on a global scale with international partners.

When Rentschler looked back at a half century of aviation, he claimed that 75 percent of the progress was due to the aircraft engine’s astounding evolution. When we look back today at a century of progress, we can see that Rentschler was probably right. Engines have gone from the Wright brothers’ level of 100 pounds of thrust up to more than 100,000 pounds of thrust today. Commercial aviation since the DC-3 of the mid-1930s has grown exponentially because of aircraft engine developments. Aircraft engines, since the early Boeing and Douglas jet-powered aircraft, have cut specific fuel consumption by about 50 percent. In his Account of Pratt & Whitney Aircraft : Rentschler wrote:

When I came to Hartford in 1925, I hoped to do more than just establish a company. I had learned the value of the power plant to the airplane. George Wheat (P&W Public Relations) later coined the expression that the ‘engine is the heart of the airplane.’ It was my original belief that if we could build the finest power plant in the world, we would be making the finest possible contribution to our national defense. We realized, too, that if and when air transport developed the same would be true in regard to it.

Certainly Rentschler and Mead not only embodied the genius of Connecticut , but were men who, to paraphrase L. Sprague DeCamp, benefited civilization. Their work provided propulsive power to the Air Force and Navy for the allied victory over the Axis powers during WWII, enhanced our national security through air superiority, shrunk the world for economically minded travelers, and created approximately a million aviation-related jobs in the process.

Jack Connors is a graduate of M.I.T. and a retired Pratt & Whitney vice-president. His article on the Vought Corsair appeared in the 2003 Nov/Dec/Jan 2004 issue of HRJ. He is presently finishing his book, CAVU-Ceiling & Visibility Unlimited, The Story of Pratt & Whitney’s Piston and Gas Turbine Engines.

EXPLORE!

“The Miracle on Capitol Avenue,” May/Jun/Jul 2004

“Sikorsky—Still Revolutionary,” Spring 2014

Read more about Connecticut industrial history and innovation with

The Connecticut Brand Collection

6 issues: $35 (a $49 value!)

This collection features stories on Connecticut’s manufacturing and industrial history. You’ll read about products—some well known, some surprising—that were made or conceived in Connecticut. Delve into the places and people that made these products, and how Connecticut’s manufacturing past impacted the day-to-day lives of Connecticut’s people in places like Bridgeport, New Britain, Waterbury, and more!

Or on our Made in Connecticut TOPICS page.